In 2013, some incidents happened on our premises. So we’ve raised this issue on Health and Safety Committee’s (HSC) meeting in Dec 2013 that how we stop incidents related to alcohol. HSC members including Directors supported Anti-Alcohol program.

We’ve prepared "Negative effect of Alcohol" educational training for our employees and announced 2 months ago to them that starting from Feb 1st, 2014 we are going to engage blow test at workplace and aware all. Written procedure had been approved by Management.

Alcohol test process requires Huge Leadership such as Directors starts to blow first and shows visible leadership to all and then everyone follow them. Initially, we were testing every day, a year later its frequency became random in a week.

Unfortunately, in Mar 2014, our 5 good employees were fired due to blow test positive results and it was big messaging for workforces that Zero Tolerance of Alcohol at workplace.

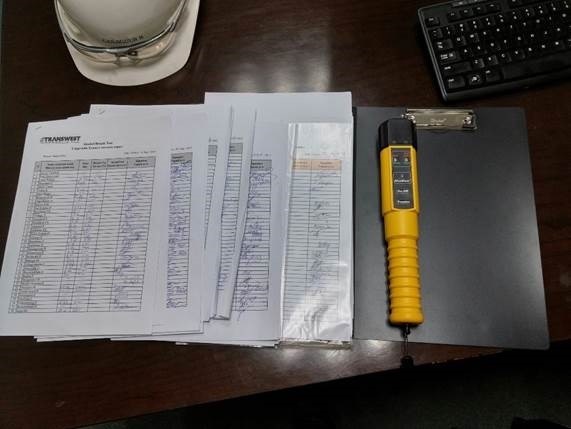

Equipment we use:

- Draeger with straws.

- Alcoblow (strawless) – lionlaboratories.com

- Alcolizer for self-testing before workhours.

PS: Here we use straw less equipment Alcoblow (yellow equipment as shown on photo) for mass testing and sign off sheet because when we use Draeger with straws, straw cost will be 1.400.000 MNT annually (700USD), used plastic straws pollute environment and detection time is around 20sec per employee as well. Alcoblow sensor capacity is +/-0.001 and detection is good within 5 sec per employee.

Self-test area is provided for Head Office and Service employees at 2 areas. If result is positive before work hours on self-test, an employee should notify his/her Supervisor and get unpaid leave for a day (without disciplinary action). If caught during mandatory random blow during work hours, it leads to termination.

Since then, we’ve ZERO INCIDENT related to alcohol for 2 years and still keep blowing during work hours random in weekly.

----------------------------

Ganjiguur Bukhbat

TheSafetyPoster.com