Life of safety helmet needs to be considered first. Because polyethylene which is common used plastic material for hard hat, degrade in 3 years as recommended in Section 3 of Australian Standard AS/NZ 1800:1998 code details the "Care and Maintenance of Occupational Protective Helmets", and Section 3.4 covers the “Working Life”. Please, include self-life for consideration as well. For instance: an MSA hard hat indicates its manufactured dates at the bottom of hat peak.

Second, stickers, labels and markers are used to mark hard hats so that important information can be shared such as indicating a worker's training or qualifications. But remember paint or permanent markers can degrade the plastic in hard hats; instead, labels or masking tape are often applied to a hard hat with the worker's name written on it. Beware, as some of the glues used for the sticky label react with the helmet shell and the hardness of the hat may be compromised.

Third, if a helmet has been stored in direct sunlight or sitting on a shelf exposed to heat (inside a locked car for example), in chemical environment, the quality of the helmet will have deteriorated. There are instances of helmets shattering when used after being stored in direct sunlight for extended periods of time.

Fourth, dust is collected on safety helmet peak and when wearing/removing the helmet, dust falls into eyes. Especially it happens at Construction, Welding and Grinding workshops. So we need to remind employees that clean the cap peak on regular basis.

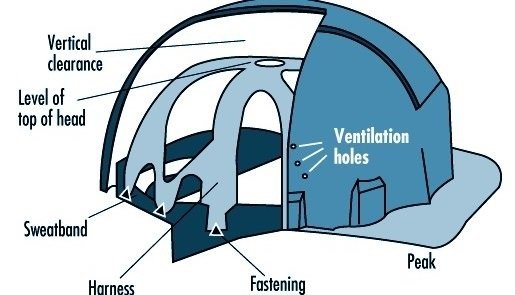

Fifth, sweatband of webbing suspension harness often gets dirty and its suitable environment to incubate germs especially in hot environment. It need to be replaced as requests of employees and prohibited to change hard hats each other.

Last, any damages on hard hat must be reported to Supervisor and replace new one. Some employees love to keep and wear their old hats with bunch of stickers, its individual protective equipment not a souvenir or relic.

----------------------------

Ganjiguur Bukhbat

TheSafetyPoster.com