Ergonomic is the first priority because unfit glasses reduce the habit of employees to use. In my country (Mongolia, in Central Asia), people have big chins and small noses and sometimes western glasses bridge doesn’t sit on nose properly, but on chins. It creates the gaps around the nose or sides of the face and foreign material penetrates to eyes through this space.

Second, wearing prescription dress (regular) glasses are not protection as safety glasses. Some people add side shields to prescription dress glasses thinking you’re more protected. It’s big mistake.

Third, choosing the wrong eye protection for the job is essential. The wrong choice may not provide the protection you need based on your work, whether it is related to temperature, moisture, light or any other factor. For example, you could have poor vision wearing the glasses due to fog, scratches, reflection, bright lights, or even too much tint or shading. Do not wear dark glasses in workshops or confined areas.

Fourth, check the glasses arm. Some glasses have hard plastic arms may cut ear back when it’s being hit. I saw this case at Drilling site in 2006.

Fifth, when an employee reports any dizzy effect when wearing safety glasses, replace it immediately.

For your information:

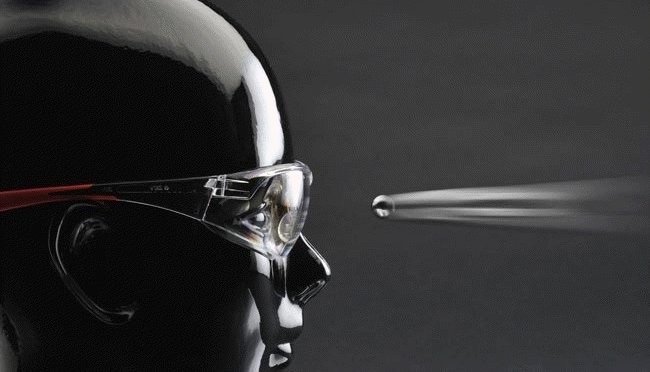

The American National Standards Institute (ANSI ) for lenses and frames are based upon the following testing criteria. Basic impact lenses must pass the “drop ball” test, withstanding the impact of a one-inch diameter steel ball dropped from a height of 50 inches. High impact lens testing requires a high velocity test whereby a quarter-inch diameter steel ball is shot at a speed of 150 feet per second. In order to pass, the lens must not crack, chip or break.

Safety frames are also subjected to testing in order to comply with ANSI standards. The testing is based on high mass impact, durability and high velocity impact. The frame must withstand the impact of a one-inch diameter steel projectile weighing 17.6 oz dropped from a height of 50 inches onto a safety lens mounted in a safety frame. It must also withstand the shooting of a quarter-inch steel ball at a velocity of 150 feet per second from a distance of just under 10 inches at different angles and positions of impact. The frame must fully retain the lens in order to pass inspection. The frame must also pass a series of durability tests including flammability-resistance and corrosion-resistance.

Fact information

“Believe it or not, the average home is full of dangers that often go unnoticed. In fact, accidents involving common household products cause 125,000 eye injuries each year. Ninety percent of these eye injures can be prevented through understanding, safety practices and the use of proper eye protection.”

“Eye injuries in the workplace are very common. More than 2,000 people injure their eyes at work each day. About 1 in 10 injuries require one or more missed workdays to recover from. Of the total amount of work-related injuries, 10-20 % will cause temporary or permanent vision loss. Experts believe that the right eye protection could have lessened the severity or even prevented 90% of eye injuries in accidents.”

“More than 40,000 people a year suffer eye injuries while playing sports. For all age groups, sports-related eye injuries occur most frequently in baseball, basketball and racquet sports” as stated at http://www.preventblindness.org/

-----------------------------

Ganjiguur Bukhbat

TheSafetyPoster.com